smart Manufacturing Approach

Manufacturing EVs of the future

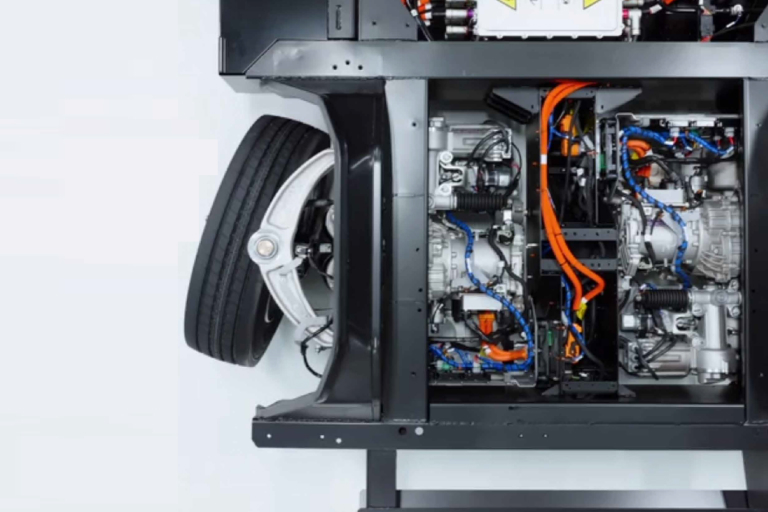

REE’s state of the art integration center in the UK brings together the very best in technology and unrivalled expertise to assemble the innovative REEcorner™.

Our team of manufacturing experts, together with leading partners and suppliers, have built an industry leading assembly line that’s designed with the future in mind and supports the exciting growth of REE’s next generation technology.

Key Highlights

Assembly Cells

Operators

AGVs

AMRs

Components

Manufacturing Partners

Advantages of Cloud-Based Robotic Assembly

This approach will allow us to remain a comparatively asset-light enterprise and reduce the overall carbon footprint of our global operations.

Component assembly at integration centers without complex manufacturing

Assembly cells and production lines can be efficiently lifted and installed at future integration centers as required as we apply one global standard using the plug-and-play format.

“No Faults Forward” methodology with integrated quality control, error proofing, and traceability mechanisms deployed throughout

REE works with top supplier partners including Rockwell Automation’s Plex Manufacturing Platform on the assembly line, and line-side controls. The Plex cloud-based solutions give us the ability to have complete visibility into all production operations and enable us to scale manufacturing locally and across global integration centers which are linked to our control room center where we can achieve an overarching view from a build perspective along with full traceability for our REE solutions.

Manage operations seamlessly from the order through delivery.

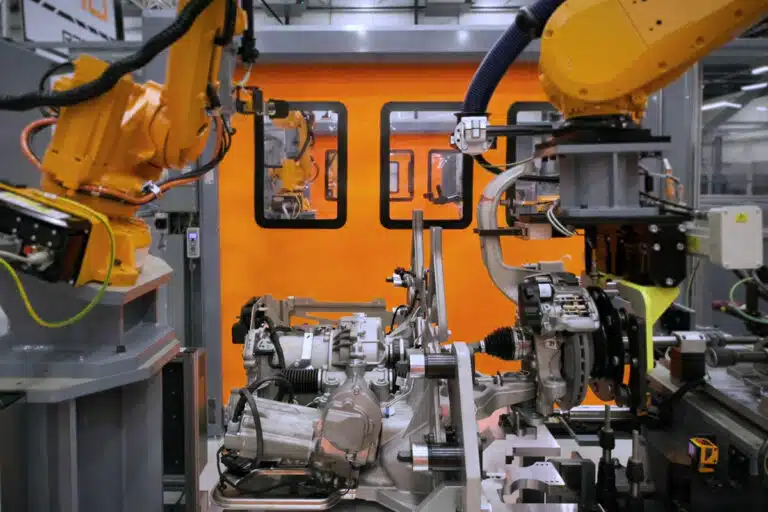

Advanced robots are deployed across our auto stations to maximize assembly line efficiency

What's New at REE?

REE Automotive Reports Fourth Quarter and Fiscal Year 2023 Financial Results

REE has accomplished the majority of its milestones as the first to commercialize full x-by-wire technology, setting the path for sustainable growth

REE Automotive P7-C Receives CARB Certifications

Powered by REE P7-C electric truck is eligible for sale in California. With CARB certifications the P7-C is eligible for over $100,000 in state and federal incentives.